|

Ningbo Paul Friction Material Co.,Ltd

|

Potassium Hexatitanate (K2TiO13) For Friction Material

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Potassium Hexatitanate (K2TiO13) also write (K2O6TiO2) is a kind of reinforcement material for making friction material.

Potassium Hexatitanate (K2TiO13) also write (K2O6TiO2) is a kind of reinforcement material for making friction material.

Performance of Potassium Titanate Whisker

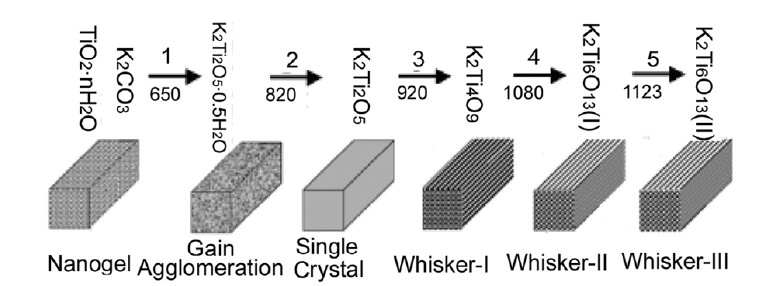

The chemical formula of potassium titanate Whisker is K2O · 6TiO2.

The crystal structure of potassium titanate is triclinic, space group C2 / m, with unit cell

parameters a = 11.37À, b = 3.80À, c = 6.62À, β = 100.1 º, the number of molecules in the unit

lattice 2. In six of the crystal structure of potassium titanate, Ti coordination number is 6, in order

to TiO6 octahedron edges through the co-planarity and co-link chain made the tunnel-like structure,K + ions residing in the middle of the tunnel, the tunnel axis and the crystal axis parallel to . The detailed crystal structure see the back of the crystal structure diagram.

Description Performance

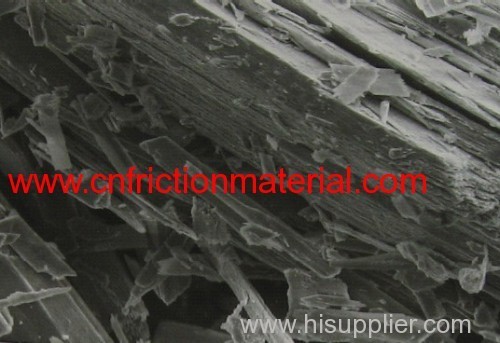

Appearance | White layer shape or rod shape crystal

|

Real Density | 3.2±0.1

|

Bulk Density | 0.7~0.8

|

Moisture Absorption (wt.%) | ≤0.3

|

Moisture Content | ≤0.1

|

Moh's Hardness | 4

|

Pure of K2Ti6O13 (wt.%) | ≥95

|

Crystal Length Range(μm) | 10~50

|

Crystal Dia. Range(μm) | 0.3~1.0

|

TDS | 3~5 ppm

|

Packing | 25kg in plastic bag and put in a drum

|

1. Excellent chemical stability

Expressed in non-moisture absorption, under normal circumstances is not with acid, alkali and salt from a chemical reaction, not soluble in organic solvents and so on. Role: for the external walls,ships coating expressed as acid and alkali erosion, due to its excellent physical-oriented, can make a one-way outside the wall of the water vapor discharged, so that exterior paint is not easy to blister, the production has been quantified . Used in power plant desulfurization devices, expressed as temperature, sulfur dioxide gas corrosion-resistant, anti-dust erosion.

2. Good mechanical properties

Mainly used in plastics, light metal such as reinforcing material. Potassium titanate whiskers with

six instead of glass-fiber thermoplastic FRC, similar in performance under the premise of the

GFRC overcome the following disadvantages: easy to deform after the workpiece ejection;

workpiece surface is generally more rough; or complex shapes for precision forming system pieces of resin and glass fibers due to the mobility of different, and in some parts, such as the end of such zones will appear depleted fibers; if there is joint, then the seam with the surrounding rigid significantly different; molding machinery and mold damaged. With six of potassium titanate

whiskers to replace the traditional asbestos friction materials, friction coefficient hardly changes

with temperature changes of asbestos fibers products to overcome the friction coefficient

significantly increased, resulting in "Hugging" phenomenon.

Role: It is now used for brake pads, plastic modification enhanced, rubber modified to enhance the aircraft manufacturing industry added to the light metal in the effective strength of reinforced

metal. Added to the special coating that can be an effective anti-friction.

3. Excellent thermal insulation properties

The thermal conductivity of potassium titanate whisker smaller, room temperature 5.4W/MK, 800

℃, when only 1.7W/MK, which has a negative temperature coefficient. Compared with the

traditional asbestos insulation materials, potassium titanate whiskers are the following

salient features: top five harmless, stable performance; the use of high temperatures, the use of

temperatures up to 1000 ℃; life long; no "ashing" phenomenon production, does not pollute the

environment. The traditional alternatives to asbestos-containing materials, whether it is

performance and cost, potassium titanate whiskers should be said that is an ideal material of

choice.

Useage: A. high-performance and high-temperature thermal infrared reflectance characteristics of the negative conduction at this stage has been involved in the pilot phase of production of

crystalline silicon. Our country is now producing crystalline silicon crystals melting rate of 17% of our subjects in this study is the crystallization rate of crystalline silicon up to 60% -70%.

B. at the same time in order to successfully apply coatings.

4. High infrared reflectivity and high temperature acoustic properties of Potassium Titanate

Whisker

In fact, potassium titanate whiskers of high infrared reflectivity, but also potassium titanate whiskers as the insulation materials is an important one of the reasons.In fact, the use of potassium titanate is not just above them, followed by more detail. At present, potassium titanate is mainly used in functional plastics and coatings materials. For the plastics increased, has been used for PP pipes, PP pipes can make use of the temperature reached 120 ℃, and, to improve the insulation performance is very obvious, 100 ℃ of water steam pipe, the surface temperature is lower than 40 ℃, can be a traditional pipeline insulating layer completely abandoned, both beautiful and generous, but also reduce costs. For the coating material, the use of plasma spraying or flame spraying and other methods can be directly sprayed potassium titanate whiskers to the base material of the surface to replace the surface of ceramic or enamel, and glass-lined coating, can be overcome either ceramic or enamel, and glass-lined coating the surface of impatience mechanical shock resistance and non-heat shock performance, while on the train in the machine, milling, grinding, to achieve smooth surface requirements, but also play a role in the insulation. For the six made into a coating of potassium titanate whiskers, potassium titanate whiskers major play to change the mechanical strength, increased wear resistance, improved temperature-resistance, anti-ray radiation to improve performance, extend service life, mainly for applications that require both the resistance high-temperature corrosion resistance but also with the special requirements of the paint.

5. High-performance self-cleaning

The inorganic salts are used in nano-technology, using the paint to add this product, after the

smooth surface a greater extent than the glass wall several times, microorganisms can not be

attached. The long-term contact with water used for swimming pool wall surface, easy to grow

moss, plants and other parasites. Surface can be used to improve the speed of ships.

In fact, the usage of six potassium titanate whisker is not just above them, we will discuss the more details later.

Currently, titanate whisker is mainly used in functional plastics and coating materials. For enhanced plastic has been used for PP pipes, PP pipes can make use of the temperature reached 120 ℃, and, very significantly improved thermal performance, 100 ℃ water steam pipe, the surface temperature is below 40 ℃, can be the traditional pipeline insulation completely abandoned, not only beautiful, but also reduce costs. For the coating material, the use of plasma spraying or flame spraying method, potassium titanate whiskers can be directly sprayed to the surface of the substrate materials to replace the surface of ceramic or enamel and glass-lined coat, not only can overcome the ceramic or enamel and glass-lined Mechanical shock surface coating impatience and non-thermal shock resistance properties, but also in machine tools, milling, grinding, to achieve smooth surface requirements, but also play a role in insulation. For the coating material made of potassium titanate whiskers, potassium titanate whiskers major play to change the mechanical strength, increased wear resistance, improved heat resistance, increased resistance to optical radiation, to extend the service life, mainly for needs of both the resistance high temperature corrosion resistance but also has special coating requirements

The difference of our potassium titanate whisker between other manufacturer's products

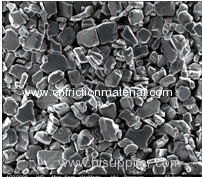

1. Our company produced products are rod-like potassium titanate / flaky crystal, with crystal basic performance, such as brittle fracture, etc., while other manufacturer's products are needle-shaped body of a floc. This flocculation needle-like body of its light weight, is mainly used for reinforced material.

2. The difference between the bulk density: Our potassium Titanate whisker 's bulk density is

slightly larger than the other manufacturer's products, our potassium titanate products bulk density is 0.5 ~0.8, the other manufacturer's potassium titanate is 0.3 ~ 0.6.

3. Enhance the material in mixing difference: our potassium titanate whisker are easy with a

variety of potassium titanate substrate material mixing, mixing time is short, but the other manufacturer's products because it is flocculent body will float on the surface of the matrix material, mixing required for a long time.

4. Our potassium products can be granulation of potassium titanate treatment. According to some special needs, my company potassium titanate according to customer demand products, all kinds of granular to meet customer's specific needs. In general, other manufacturer's titanium potassium products are very difficult to granulating.

5. Our products can be use of a potassium titanate special method making potassium titanium

coating, substitute some special needs, such as high temperature resistance, cold shock and wearresistant coating such as potassium titanate, and the other manufactuer's product is difficult to meet this requirement.